- Main parameters of the machine

- Main features of the machine

- Main machine specifications

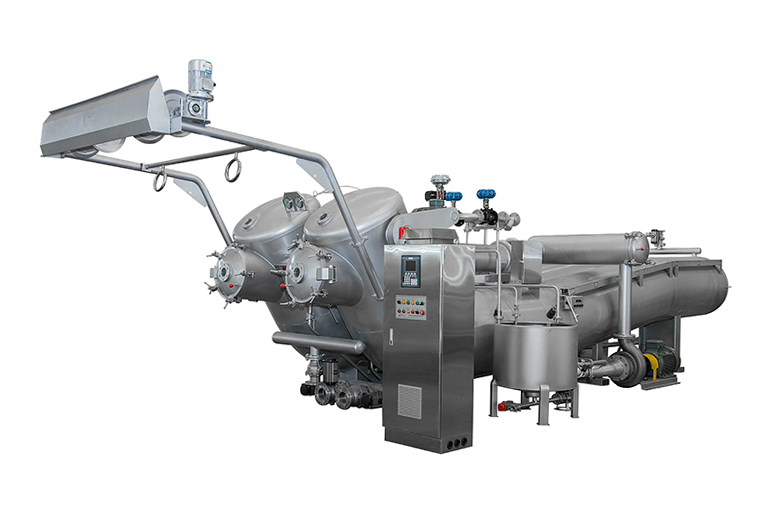

* Machine type: long cylinder

* Design pressure: 0.44Mpa

* Working pressure: 0.4Mpa

* Design temperature: 140℃

* Working Temperature: 135℃ * Rising Speed: 20℃~130℃ about 35 minutes (saturated vapor)

* Rising speed: 20℃~130℃ about 35 minutes (saturated vapor pressure is 0.7Mpa)

* Cooling down speed: 130 ℃ ~ 80 ℃ about 25 minutes (cooling water pressure of 0.3Mpa) Cooling water temperature: 5 ℃ ~ 10 ℃

* Bath ratio: as low as 1:4 ~ 5

* Ultra-low bath ratio, bath ratio can be as low as 1:4 to 1:5.

* Large capacity, capacity can be increased by 50% output on the basis of the original.

* The crease-prone fabrics can be pre-shaped less than once, saving costs.

* Low energy consumption per ton of cloth (save 50% each of water, electricity, steam and auxiliary on the original basis).

* Built-in composite variable-diameter type cloth guide tube: reduces tension to a small amount and effectively removes warp crease function.

* Overflow and jet nozzles are available: suitable for dyeing a wide range of fabrics with grammage weights from 50 to 600 g/m2.

* Low machine height, low tension, small shrinkage after dyeing, and easy to achieve finished yardage weight.

* Simple operation and maintenance.

|

Machine specifications and models

|

Fabric capacity (KG)

|

Number of tubes/troughs

|

Installed power (KW)

|

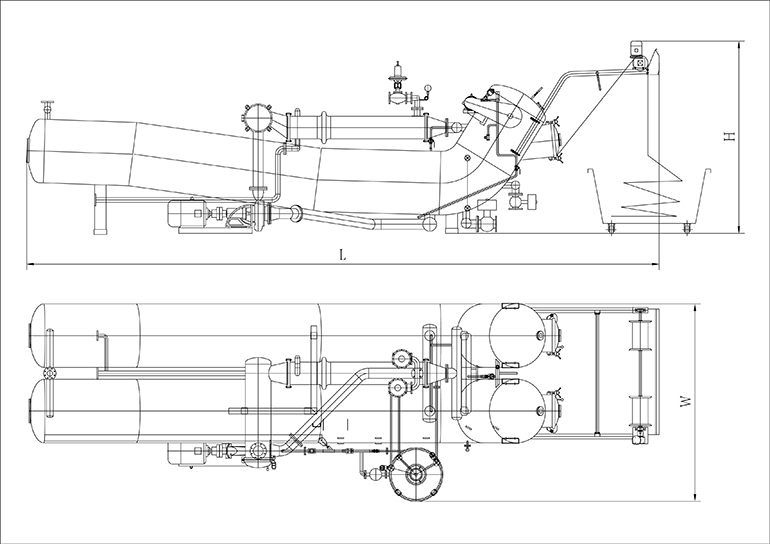

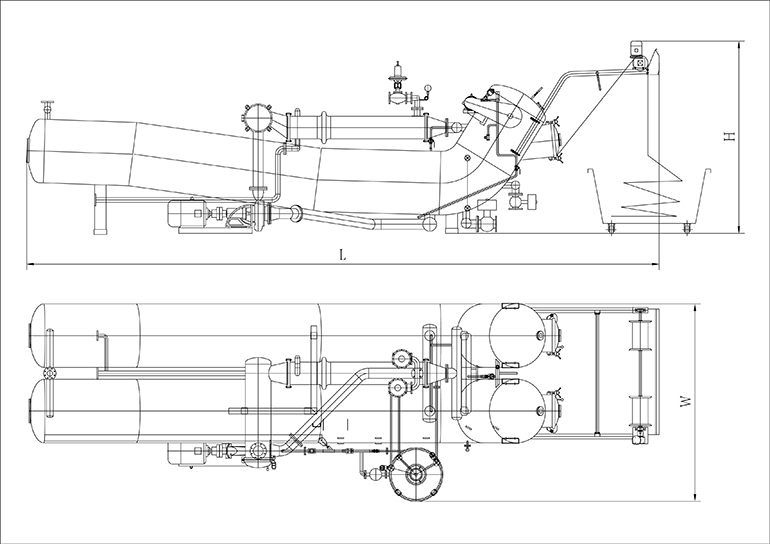

Overall dimensions (L×W×H)

|

|

TH-LA-1B

|

200~300

|

1/2

|

20.2

|

10062x1867x3060

|

|

TH-LA-2B

|

400~600

|

2/4

|

37.4

|

10062x3152x3060

|

|

TH-LA-4B

|

800~1200

|

4/8

|

68.3

|

10062x6072x3160

|

Scan the QR code to follow us

Scan the QR code to follow us